Writing was on the wall for Burnley’s cotton industry

“If you are an Arctic explorer or a mountain climber your blizzard-proof clothes and tents very likely are made of Grenfell Cloth which is also made in Burnley in the mills of an old established firm owned by a family with the most delightful name of Haythornthwaite, a name which, I think, more properly belongs to the neighbouring counties of Cumberland and Westmorland rather than to Lancashire”.

These are the words of author Walter Greenwood and come from his volume “Lancashire” in the County Books series published by Robert Hale Ltd of London in 1951. If you want to find out what Lancashire was like in these days, and how it had reached its status at that time, you could do no better than avail yourself of a copy. You would also remind yourself what a good writer Walter Greenwood, author of “Love on the Dole”, actually was.

Advertisement

Hide AdAdvertisement

Hide AdWhen rereading Walter Greenwood’s “Lancashire” I was struck by the contrast that book and another, “Lancashire, Cheshire and the Isle of Man”, Freeman et al, Thomas Nelson and Sons Ltd, 1966, made with the optimism for the Lancashire cotton industry in the days of its world dominion.

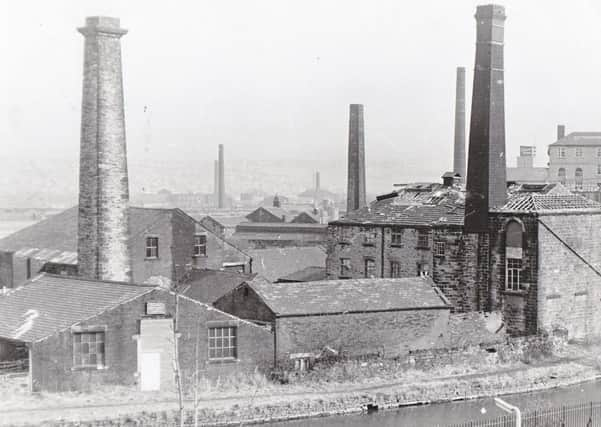

As you know, in Peek into the Past, I have been writing about Burnley as a cotton town. It is a remarkable story and the evidence is all around us, almost a generation after the industry’s “final bow”, reminding us the importance, in the past, of the industry to our town.

In today’s article I want to look at Burnley’s cotton industry at the time, and just after, Walter Greenwood wrote about it. He makes the point that Burnley produced the finest cotton poplin used in the making of shirts. In this he is only partly right in that though Burnley did make poplin that which was produced in Nelson and Colne was of better quality. That particular trade, the product of the fine weaving industry, lasted longer in these two towns than it did in Burnley.

Another product of the fine weaving industry was Grenfell Cloth and, with regard to this, Mr Greenwood was quite right though, by the time his book was published, things had moved on. The Burnley firm of Haythornthwaite certainly invented Grenfell Cloth which was named after Sir Wilfred Thomason Grenfell, the medical missionary who, in 1892, went to Labrador and founded hospitals and orphanages as well as fitting out hospital ships for the fishing grounds.

Advertisement

Hide AdAdvertisement

Hide AdSir Wilfred became known as “Grenfell of Labrador”. He had let it be known he could make use of a waterproof and breathable material for his work in the Arctic conditions of North America. James Haythornthwaite, from Burnley, came to his aid and invented the finely woven material, named after Grenfell. It was waterproof and, because it contained no rubber, was breathable. This was a big step along the road to a whole new industry, one which differed from that which had been founded by Charles Macintosh some years before. The latter had rubberised the material he used in producing “macs”, as they were called. They were waterproof though they were not breathable and, as a result, had limited use in the Arctic.

The new industry which Haythornthwaite founded was that of what we now call the “outdoor clothing industry”. In more recent years materials inspired by Mr Haythornthwaite have been invented for making into shoes, sleeping bags and the tents to which Walter Greenwood referred. It might be thought that the initial Burnley invention might have been fully exploited in its home town. For a time it was and Grenfell cloth was used on the mountaineering expeditions of the years between the two World Wars, but the Second World War almost did for Haythornthwaite’s as the Government closed their Lodge Mill down for the duration.

By the time the war was over, the lead that had been established in Burnley in this now very lucrative industry, was over. Some of you will remember Lodge Mill in Barden Lane as the “home of Grenfell Cloth” and will recall the more recent days when the firm occupied a mill in Rylands Street. This latter building was, I think, unique in Burnley in that it was the only building in town to carry a Royal Warrant. The firm also had premises for the making of clothing at Duke Bar.

However, along with the vast bulk of Burnley’s cotton industry, the firm no longer exists. This situation applies to the whole of Burnley’s fine weaving industry with the single exception of Spencer’s at Ashfield Mill.

Advertisement

Hide AdAdvertisement

Hide AdI should point out that, though all of the towns between Blackburn and Colne constituted the old weaving belt of North-East Lancashire, the towns themselves did not make the same types of cloth. This had never, strictly, been the case in the past, but, by the decades which followed the conclusion of the First World War, Blackburn had become particularly associated with the production of course grey cloth, mainly for tropical markets. Burnley and Accrington made medium quality material with some fine cloths. Nelson and Colne, and the area around the two towns, dominated the fine weaving sector.

Another factor to take into account is the importance of mill work in individual towns. Statistics are available for 1914 and in that year 63% of all ensured employment in Blackburn was in cotton. In Burnley the figure was an astounding 72% though even that pales into insignificance when compared to Great Harwood at 83%!

Alternative employment was not available in suitable numbers throughout the area for both sexes, especially in the smaller towns and among women. In Burnley, for example, nine in every 10 women were mill hands. Mines were unable to provide jobs. The shallow seams of the Blackburn area had already been exhausted. The deeper mines of the Burnley Coalfield employed less than one-tenth of the local labour force.

Freeman et al, in his 1966 study adds “by 1914 North-East Lancashire was distinguished by the narrowest industrial economy in the Lancashire coalfield: it depended on a single branch of a single industry”. He goes on to say “the weaving belt of Lancashire could be classed with Jarrow, West Durham and South Wales in the extreme specialisation of its industrial economy and when the depression struck the area it did so with great force, though with local variations in its impact”. In the 1930s it was Blackburn that suffered the most, at least in the number of job losses in cotton textiles. Between 1931 and 1951 Blackburn lost two thirds of mill employment whereas the losses in Nelson and Colne amounted to only one third. The reason, it has been suggested, that Blackburn suffered most is that the manufacturers in that town could no longer sustain the fight for markets in Asia. Indian firms, for example, had been deprived of Blackburn cloths during the war years and, in that time, had invested in new buildings and machinery which, together with low wages that applied their, meant an important market was lost.

Advertisement

Hide AdAdvertisement

Hide AdNelson and Colne, although there were losses, were able to deal with the newer industry being established in Asia and, to some extent; Burnley was in a similar position. This accounts for Walter Greenwood’s comment, in 1951, that Burnley was still producing cotton poplins for shirts which was admired the world over. That might have been true but the local cotton industry was continuing to decline and this can be seen in the fall in the population of the town. Between 1931 and 1951 the population of Burnley fell by 13.5% and between 1951 and 1961 it fell by a further 5.3%.

If we look at Blackburn, the town which lost two-thirds of its mill workers, the decline in population there (1931-51) was only 9% and, in the following decade, the decline, at 4.5%, was still less than that taking place in Burnley.

At first sight these figures might not seen to make sense. However, from the 1930s Blackburn was much more successful in remodelling its economy than the Burnley to Colne area. In addition, quite a number of workers from Blackburn found employment in the newer industries of Leyland and Preston.

Of course when the depression finally came, in the early 1950s, to the middle and fine weaving area of the east of the county the shock to the local economy was very great. Unemployment rose rapidly to pre-war levels and, in 1953, the Government granted the Burnley district Development Area status in the hope the guidance of new industry into the area would restore its stability.

Advertisement

Hide AdAdvertisement

Hide AdAn analysis of the north-east of Lancashire, the NELDA area as it was called, shows Burnley had been much more successful in attracting new jobs than the area as a whole. This was the product of two factors – the town’s own success in attracting new industry (particularly Platers and Stampers) before 1939 and the decision by the Lucas Group, a Birmingham-based company) to remain in Burnley after the war.

However, what is clear is that the growth of new firms was slower than the decline taking place in cotton textiles. This was complicated by an unexpected rise in demand for good quality textiles after 1952. It did not last long but there were jobs in many of the local mills and workers whose jobs had gone at one mill could, in these years, find work in others.

I recall, when at school, in the early 1960s textile firms in Burnley were still trying to recruit young workers to their mills. One of the firms was that of John Grey Ltd. They had two large mills in Burnley and one in both Harle Syke and Nelson. If I remember correctly the firm even produced leaflets indicating just how secure were the jobs in their mills. Of course, by that time, even the young had come to the conclusion there was no future in cotton textiles in Burnley and the leaflets were left unread.

In those days the one thing most boys wanted was an apprenticeship at Lucas’s and that firm, as a consequence of Development Area status, was joined by others, notably Michelin, in Burnley, and Mullard’s, in Simonstone.

Advertisement

Hide AdAdvertisement

Hide AdUnfortunately, all these new jobs (and they were welcome) did not address the real problems. Labour continued to leave the town and a low birth rate did not encourage new industry in the numbers required. The area’s physical remoteness and indifferent communications, exacerbated by the loss of railway connections as a result of the Beeching closures, meant new companies were drawn to other parts of the country.

Then, in 1960, the Government withdrew Development Area status. This was something of a blow but it must be noted north-east Lancashire had been the last of these areas. It had not had the chance to really regenerate local industry and, to my mind, there was an inherent weakness in the system that had been established.

This was that those who ran the development schemes, and even the political parties then in power, looked upon the manufacturing as the only way forward. A way forward, yes, but only one of several ways forward. No one seemed to realise, until it was almost too late, that the economy had other sectors and these were contributing to the comparative economic success of other regions.

The decline of Burnley’s textile trade is a warning to everyone involved in commercial regeneration. Cotton reached the zenith of its importance at the time of the First World War but the industry’s leaders, at this time and even before, had “ignored the writing on the wall”. This had become apparent in the 1860s, during the Cotton Famine, when the collapse of the industry, because of the intervention of the American Civil War, lead to high levels of unemployment and great hardship.

Advertisement

Hide AdAdvertisement

Hide AdWhen the peace was signed and cotton returned to Lancashire mills all that was forgotten. The industry prospered again but, in the 1890s, warnings of impending doom were uttered again even by individuals prominent in the industry. Similarly, their arguments were ignored and when the crisis did come, and influential people out of Lancashire asked the question, “We grow no cotton, why should we spin and weave it?” no one in Lancashire knew what to do.

Eventually, the Government decided that we no longer needed a cotton industry .