When the Lord of the Manor had a monopoly on milling

I came to the conclusion the earliest of the mills were established by their respective Lords of the Manor in times when the weather was conducive to the production of corn.

In later times, when the climate became colder, it was necessary to add corn kilns to the mills so milling could take place but the original mills continued to operate and were joined by others, sometimes illegally.

Advertisement

Hide AdAdvertisement

Hide AdIn the 19th Century, though some early mills were lost and others converted for other purposes, there was an increase in the number of corn mills especially in Burnley. I speculated this was probably the consequence of transport improvements – particularly of canals and railways.

Another reason for the increased number of corn mills in Burnley appears to be the native ingenuity of Burnley men who took advantage of the changed circumstances to establish a milling industry of regional rather than local importance.

Today, I am going to look at just one mill, Burnley Mill, otherwise known as the King’s Corn Mill, which was situated on the left bank of the river Brun, just off Bridge Street in the town centre.

We know the mill was in existence as early as 1290, that it was driven by a water wheel turned by the river and the Brun was dammed to create a regular and steady flow of water for the mill.

Advertisement

Hide AdAdvertisement

Hide AdIn fact we also know there were actually two dams, the first, properly a weir, on the river just below what are now the grounds of Bank Hall and the second, a dam nearer the mill. The former took water from the river and delivered it to the latter by means of a mill race, or goit, the route of which can still, in part, be identified. The dam was designed to store water so the mill could extend the times of its operation.

Surprisingly, perhaps, the weir is still in place and can be seen through the railings opposite the Old Grammar School Gardens. Of course, what is there now is not the original weir and there is some dispute as to whether this was its original site. However, the Burnley Weir, as it is correctly called, is about to become part of a renovation scheme, managed by the Ribble Rivers Trust. The scheme will remind people not only about the weir’s former importance but also, because it has slipped from public consciousness, of its very existence and is, therefore, much to be commended.

The site of the dam near to that of the mill is known though there are no remains today. As might be expected, the dam became known as the “Mill Dam” and, as it was awkwardly situated restricting access to other property in the area, it was a prominent feature of this part of Burnley. When, in c1780, another mill, this time built for the worsted industry, was constructed nearby it was named Mill Dam Mill and this building was still standing when I was a boy.

Another thing that has survived is the site of the mill pond created by the Mill Dam. There is no water in the pond these days but its site almost exactly coincides which the small car park behind the present Bridge Bierr Huis, that building constructed on the site of the Mill Dam itself.

Advertisement

Hide AdAdvertisement

Hide AdIt is remarkable that, after all these years, it is still possible to locate where these ancient structures were built.

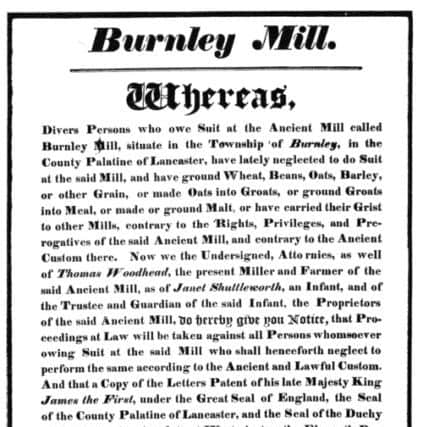

Burnley Mill was a manorial mill. It was the Soke Mill, the official mill to which all tenants of the Lord had to take their corn to be ground into flour. This did not only apply to the corn – wheat, oats and barley – grown on the lord’s land, there was usually a stipulation that if any corn was bought outside the manor it still had to be ground at the Soke Mill if it was to be used in the manor. Similarly, if drying or husking were to be carried out, or oats ground into meal, the work had to be carried out by the lord’s miller.

We know a little about what the mill of 1290 looked like. This can be gleaned from the surviving records relating to the Manor of Ightenhill of which Burnley was part. The earliest mill is likely to have been constructed out of timber and the roof will have been a thatch, not of straw, perhaps, but of reeds.

Of course, the water wheel would have been made of wood which, like almost all the other materials used, would have come from local sources. The grinding stones were of grit stone which may have been local but this material could have come from east of the Pennines where the local stone is more suitable for grinding.

Advertisement

Hide AdAdvertisement

Hide AdIn 1342, it seems the mill was re-erected and, from the surviving accounts, we know a lot about the work carried out. A carpenter was paid 7s 4d (36p) for cutting the timber for two wheels and what was called the “out shore”, in other words, the mill race. A further 1s 6d (c7p) was spent to carry wood to the mill.

One “clamp of iron” at 1s 6d was ordered as was 10 stones of iron bought for the “new weir”, new axle and other iron work. A smith was hired to shape the wheel and he was paid 1s 8d (c9p) for his efforts. Incidentally, it is not known where the iron came from but there are known to have been several bloomeries (an old term for the early equivalent of an iron furnace) in the Burnley area in the middle ages, so the iron too might have been local.

A mason was hired to cut and lay the stones. This refers not to building stones but to the grinding stones where the corn was made into flour or meal. There was also payment for the collecting, cutting and binding of rushes “in the wood and carrying them to the mill for four days at 2d (1p) per day”. Unfortunately, we do not know which wood was the source of the rushes. In those days Burnley was a much more heavily wooded area than today. A “roofer” was paid for four days work also at 2d a day.

From this we can work out that, though we have no indication of its size, the mill may have changed very little from the original building. A large amount of wood was used in the rebuilding process and it is likely most of it was used to make the framework for “wattle and daub” walls. More would have used in the making of another framework to support the thatched roof. It could be that the wood-supported walls stood on stone foundations but this is not certain.

Advertisement

Hide AdAdvertisement

Hide AdAnother thing about which there is no degree of certainty is the type of water wheel used in Burnley’s first mill. As we saw last week, many early water wheels were horizontal but there were also undershot, breast shot and overshot water wheels, all of which were known to the Romans. However, that the mill was thatched is certain and this is confirmed because of work known to have taken place at Burnley’s neighbouring fulling mill. This was repaired in the same year (1342) and, in the accounts that relate to this work there is reference to “straw, bought for the roof of the mill, 1s 0d” (5p). This merely indicates the skills were there to construct roofs out of thatch, whether they were of straw or reeds.

At the fulling mill there was also work for a carpenter, a roofer and mason but very little money was spent on this project when compared to that spent on the corn mill.

The story of the mill from the middle of the 14th Century is not entirely clear. It is known the mill became the property of the Crown in 1399 when Henry IV became king and that, from then on, was known as King’s Mill. Unfortunately, we do not know when the mill was rebuilt in stone. However, in 1423 the mill was leased to a William Fox for a rent of £3 7s 4d a year and again, from documents that have survived, we know Mr Fox had to keep the building in good repair except for the main timbers which the Crown found for him through the agency of the Master Forester, probably an office holder of the Forest of Pendle.

In 1423 new millstones were brought from Yorkshire and carted to the mill. A new mill wheel was constructed, a new axle-tree was made and two “bolsters” of iron were placed under the axle. In addition, two hoops of iron were made and 20 cartloads of timber were ordered and delivered. Six beams of wood from West Close, near Higham, were delivered and more timber was brought from a site in Padiham. The mill dam was repaired and the thatch roof may have been replaced with a stone one at this time.

Advertisement

Hide AdAdvertisement

Hide AdHowever, we do not know for sure about the amount of stone in the building. The reason why it is thought the thatched roof was replaced by a stone one is because the timber roof supports were strengthened. It is likely the mill could have been largely of stone by the 17th Century when the Shuttleworths of Gawthorpe took the lease. We know that, in 1704, there was a considerable flood in Burnley and the weir serving the corn mill was a casualty. A new weir replaced the one lost and further work was done to the mill race, or goit, in 1715.

Mr Bennett, in his History of Burnley, describes the mill as an “isolated stone building” when referring to it as it was in the early 18th Century. At the end of the century the land around the mill began to be developed. What was to become known as the “Old Brewery”, later Hargreaves’ Old Brewery, was built on a plot of land adjacent to the mill. It is thought the builder was Henry Crook, the third in a family of early Burnley businessmen, who had taken over the corn mill and who also built nearby Swallow Hall, later the Market Tavern. We have already seen Mill Dam Mill was also built at this period.

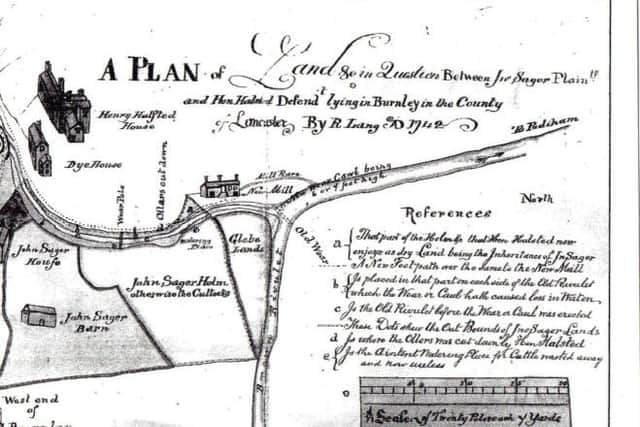

In 1742 a map was produced of the Bridge End area of Burnley. It does not show the site of Burnley Corn Mill but it does show a building described as the “New Mill”. As you can see, it is situated near the confluence of the Calder and Brun, on a plot of land probably the site of Burnley’s last operative cotton mill, Spencer’s.

On the map there is a drawing of the New Mill. It is shown to be a stone building, with a stone roof and three chimneys. On the left, the building is of a single storey, on the right it is of two storeys. The building looks rather like a farm house with a barn attached except there appears to be a door at first floor level and there might be an attempt to show stairs leading to that door.

Advertisement

Hide AdAdvertisement

Hide AdThe New Mill was not constructed to grind corn so we have to be careful about how we use its existence in Burnley at this time. However, it seems more than likely the corn mill, though larger, would have been of similar construction. It is possible to say this because, as to some extent we have seen, the very nature of a corn mill makes renewal and reconstruction a regular occurrence. It was not only the situation of a mill – by a river – that caused problems but some of the machinery was in direct contact with the water. Also the way flour was made was very abrasive necessitating constant maintenance of machinery and the structure of the building.

In other words, it would have been efficient to replace a largely wooden building with a stone one whenever that could be afforded. We know that Burnley, from about 1570, started the process of becoming what it has remained until recent times, a stone built town. The mill would have been subjected to the same changes.

The King’s Corn Mill remained in the hands of the Shuttleworths and it was they who sublet the building to the Crooks who were joined by the Tattersalls and the Sagars. Matthew Greenwood was the miller from 1814 to 1823 and this brings into our story the first mention of the Greenwood family which, from this time, was to play a significant role in the story of Burnley’s corn milling industry.